Most parts in stock and ready to ship. Orders fulfilled in 1-3 business days.

Get a free Clutch Masters shirt and the option of free ground shipping within the Continental US with purchases over $300.

Most parts in stock and ready to ship. Orders fulfilled in 1-3 business days.

Get a free Clutch Masters shirt and the option of free ground shipping within the Continental US with purchases over $300.

Clutch Masters is proud to manufacture the finest multi-plate clutch systems available for today’s high-performance vehicles. Clutch Masters twin disc clutch systems are pure racing technology that also works in high-performance street applications that will be used on the street on rare occasions. Whatever type of car you’re driving, Clutch Masters Industries can help add clamping pressure without exaggerating the pedal pressure.

At Clutch Masters Industries, we aim to provide drivers with the best dual-disc clutch systems possible. Using our decades of experience as a clutch and parts manufacturer, we’ve created twin disc clutch parts that enhance holding power without making the pedal unnecessarily heavy. These double disc clutch systems are designed to hold tremendous horsepower and torque ratings while being reasonable to operate on the track.

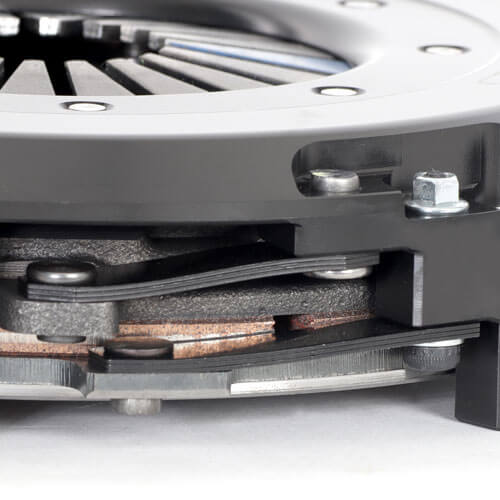

By increasing the clamping force of the pressure plate and adding to the square inches of usable disc area, Clutch Masters twin discs significantly increase clamping values with an average 50% increase in pedal pressure depending on the application. The cover assembly is machined from billet aluminum that is hard anodized and offers 25% more tensile strength than the competition’s cast unit. Twin disc flywheels are machined from billet 6061-T6 aluminum to meet SFI spec 1.2 for competition in NHRA, NDRA, IDRC, IHRA, SCCA, and NASA. Each aluminum flywheel includes a replaceable heat shield. 1045 Billet steel flywheels are also available on select applications.

If your vehicle could benefit from a twin disc clutch, Clutch Masters Industries is here to help. Browse our inventory to find one that suits your car, or contact our expert staff if you have any questions about our clutch or flywheel products.

Available Stages:

- “Street and Race” (TD7S) – 1 ceramic rigid disc, and 1 fiber tuff rigid disc

- “Race” (TD7R) – 2 ceramic rigid discs

The Clutch Masters FX725 is a 7.25" (184mm) Twin Disc clutch and is the ultimate in twin disk performance for engines/transmissions with smaller bell-housings that are focused on drag racing. Clutch Masters FX725 Twin Disc systems are developed from decades of experience in drag racing. Because of the minimal rotational mass the FX725 isn't ideal for the street but with improvements in friction material over the years we have been able to create a solution that can handle occasional street driving. The FX725 is designed to hold tremendous horsepower and torque, while maintaining reasonable peddle pressure to operate on the track.

The cover assembly is machined from billet aluminum and is then Type 3 hard anodized. Our billet covers have roughly 25% more tensile strength than the competition’s cast unit. By focusing our ability on machining the strongest cover possible while maintaining minimal weight, we are basically able to eliminate any flex in the cover. Our billet covers see only .003" of flex where as a cast or stamped unit can see as much as .030" of flex. By eliminating this flex in the cover, the driver is able to operate the clutch much more consistently and confidently. All the movement being applied to the diaphragm of the clutch from the throwout bearing is used solely to engage and disengage the clutch and isn't wasted by the cover flexing first. The strength of our covers also results in greater clamping force over the same amount of area vs. a cast or stamped cover. This means our twin discs are easy to drive and have superior clamping force to make sure all the power your engine is making is being utilized.

What makes our FX725 and FX850 Multi-Disc Kits truly special, and a feature unique to Clutch Masters is our QR System, or Quick Release Pressure Plate. The QR System Incorporates three spring-loaded bolts allowing the pressure plate to engage and disengage evenly and smoothly while reducing internal clutch noise/chatter by up to 50%. The QR System was developed to provide quiet and smooth operation for the street user while delivering the performance a multi-disc race clutch needs.

Flywheels are made for each specific application in either aluminum or steel. Our aluminum flywheels are machined from billet 6061-T6 aluminum to meet SFI spec 1.2 for competition in NHRA, NDRA, IDRC, IHRA, SCCA and NASA. Aluminum flywheels are Type 3 hard coat anodized to ensure their durability and performance lasts. Each aluminum flywheel includes a replaceable insert. Steel flywheels are machined from 1045 billet cores and are then black oxide treated for rust prevention.

Available Stages:

- “Street and Race” (TD8S) – 1 sprung ceramic disc, and 1 fiber tuff rigid disc

- “Race” (TD8R) – 1 sprung ceramic disc, and 1 ceramic rigid disc.

The Clutch Masters FX850 is an 8.5” (216mm) Twin Disc clutch is the ultimate in twin disk performance for engines/transmissions with smaller bell-housings. Clutch Masters FX850 Twin Disc systems are pure racing technology that also work well in high performance street applications. The FX850 is designed to hold tremendous horsepower and torque, while maintaining reasonable peddle pressure to operate on the track. By increasing the clamping force of the pressure plate and adding to the square inchesof usable disc area, Clutch Master FX850 Twin Discs significantly increase clamping rates with an average of 50% increase in pedal pressure depending on the application.

The cover assembly is machined from billet aluminum and is then Type 3 hard anodized. Our billet covers have roughly 25% more tensile strength than the competition’s cast unit. By focusing our ability on machining the trongest cover possible while maintaining minimal weight, we are basically able to eliminate any flex in the cover. Our billet covers see only .003” of flex where as a cast or stamped unit can see as much as .030” of flex. By eliminating this flex in the cover, the driver is able to operate the clutch much more consistently and confidently. All the movement being applied to the diaphragm of the clutch from the throwout bearing is used solely to engage and disengage the clutch and isn’t wasted by the cover flexing first. The strength of our covers also results in greater clamping force over the same amount of area vs. a cast or stamped cover. This means our twin discs are easy to drive and have superior clamping force to make sure all the power your engine is making is being utilized.

Alternatively our 850 Twin Disc can be upgraded to our DLX series. With the DLX series we have engineered a way for both discs to inherently be dampened. By directly connecting a rigid disc to the disc with the sprung hub both discs are able to transfer any shock load through to the dampened hub. Not only does this setup work incredibly well for a daily driven car making high horsepower it also is great for a race car that wants that extra protection from drivetrain shock by using a dampened clutch disc.

What makes our FX725 and FX850 Multi-Disc Kits truly special, and a feature unique to Clutch Masters is our QR System, or Quick Release Pressure Plate. The QR System Incorporates three spring-loaded bolts allowing the pressure plate to engage and disengage evenly and smoothly while reducing internal clutch noise/chatter by up to 50%. The QR System was developed to provide quiet and smooth operation for the street user while delivering the performance a multi-disc race clutch needs.

Flywheels are made for each specific application in either aluminum or steel. Our aluminum flywheels are machined from billet 6061-T6 aluminum to meet SFI spec 1.2 for competition in NHRA, NDRA, IDRC, IHRA, SCCA and NASA. Aluminum flywheels are Type 3 hard coat anodized to ensure their durability and performance lasts. Each aluminum flywheel includes a replaceable insert. Steel flywheels are machined from 1045 billet cores and are then black oxide treated for rust prevention.

Fitment:

- Fits all current FX850 twin disc applications (can easily upgrade from current FX850 twin disc to FX850 STRAPPED)

- Popular applications include; Mitsubishi EVO 4G63; Audi A3, A4, A6, Allroad, S4, RS6, TT; Honda S2000; Acura NSX; Acura TL, TSX (J30 and J35 Engines) Subaru EJ20/25 and FA20; BMW N54, N55, S54; Nissan/Infiniti VQ35/37; Nissan SR20DET, KA24DE, RB20/RB25/RB26; VW Jetta, Golf R and GTI 1.8L and 2.0L Turbo; Mazda RX-7 and MazdaSpeed6; Toyota 7M/1JZ/2JZ and Tacoma; Chevrolet LS Engine; Porsche 996 (Turbo 4, GT2, GT3), 997 (Turbo, GT3)

Clutch Masters is proud to present our FX850 Strapped Twin Disc Clutch Kit. We developed the FX850 Strapped out of necessity to bridge the gap between a single disc clutch that is easy to drive on the street and our original FX850 Twin Disc. While our original 850 Twin Disc is treatable, it was never designed with extended street use in mind. That is where the 850 Strapped is different. Utilizing drive straps to isolate the pressure plate and the mid-plate between the two discs, we are able to virtually eliminate all chatter and allow for a much smoother engagement.

This similar methodology has been proven to work incredibly well in our FX1000 and FX1200 Twin Disc kits with users reporting that their cars or trucks are able to be driven with ease on the street yet take a beating on the track, all while maintaining very manageable peddle pressure. With one sprung ceramic disc and one rigid ceramic disc utilizing the highest quality ceramic material, you can be confident that your clutch won't be slipping.

Like the rest of our twin disc covers, the 850 STRAPPED cover assembly is machined from billet aluminum and is then Type 3 hard anodized. Our billet covers have roughly 25% more tensile strength than the competition’s cast unit. By focusing our ability on machining the strongest cover possible while maintaining minimal weight, we are essentially able to eliminate any flex in the cover. Our billet covers see only .003" of flex where as a cast or stamped unit can see as much as .030" of flex. While both of those numbers may seem small, in the reality of a clutch and the minimal amount of movement they have to begin with to engage and disengage, by drastically reducing this flex in the cover, the driver is able to operate the clutch much more consistently and confidently. All the movement being applied to the diaphragm of the clutch from the throwout bearing is used solely to engage and disengage the clutch and isn't wasted by the cover flexing first. The strength of our covers also results in greater clamping force over the same amount of area vs. a cast or stamped cover. This means our twin discs are easy to drive and have superior clamping force to make sure all the power your engine is making is being utilized.

Alternatively our 850 Twin Disc can be upgraded to our DLX series. With the DLX series we have engineered a way for both discs to inherently be dampened. By directly connecting a rigid disc to the disc with the sprung hub both discs are able to transfer any shock load through to the dampened hub. Not only does this setup work incredibly well for a daily driven car making high horsepower it also is great for a race car that wants that extra protections from drivetrain shock by using a dampened clutch disc.

Flywheels are made for each specific application in either aluminum or steel. Our aluminum flywheels are machined from billet 6061-T6 aluminum to meet SFI spec 1.2 for competition in NHRA, NDRA, IDRC, IHRA, SCCA and NASA. Aluminum flywheels are Type 3 hard coat anodized to ensure their durability and performance lasts. Each aluminum flywheel includes a replaceable insert. Steel flywheels are machined from 1045 billet cores and are then black oxide treated for rust prevention.

The Clutch Masters Factory Fit FX Series Twin Discs were developed to bridge the gap between replacing the twin disc that came in your car from the factory and one of our 725, 850 or 1000 Series twin disc kits. As OE auto manufactures continue to push for more and more power, they are typically equipping those cars lucky enough to be outfitted with a manual transmission with a twin disc clutch. But what happens when the factory clutch starts to wear out or slip because you've modified and tuned the car? Lots of owners of these higher end powerful cars still want to maintain a car that is easy to drive on the street, yet take the abuse they will inevitably throw at it. Most aren't looking to go full race car and install a twin disc designed for such use, there has to be a compromise.

Our answer to these dilemmas is our Factory Fit FX Series Twin Disc Clutch Kits. Using components similar to what came in the car from the factory, our engineering team does everything they can to expand and improve upon the OE twin disc in many ways. Using higher end friction materials, lighter materials and our expertise in developing performance clutch kits for over 45 years, we dial in a twin disc kit that bridges the gap between full race car and luxury daily driver making serious horsepower.

The Clutch Masters FX Series Twin Disc kits utilize our proven friction materials found in our FX Series Single Disc Clutch kits and are available in several different configurations to suit you and your cars needs.

Pictured above is our Factory Fit FX400 Series Twin Disc replacement for the 2021+ BMW G80 M3 with 6-Speed transmission.

Our Factory Fit FX Series Twin Discs will come as a complete replacement kit utilizing a Type 3 Hard Anodized Flywheel, a custom designed steel floater, factory style stamped steel cover, and two clutch discs.

Available Stages:

- “Race” (TDKR) – 1 sprung ceramic disc, and 1 ceramic rigid disc.

The Clutch Masters FX1000 is a 10.00” (254mm) Twin Disc clutch unit designed for high horsepower applications that performs well on the track and can even withstand heavy street use. The strap-driven plate design allows for smooth engagement and minimal clutch chatter while still being able to withstand hard launching, clutch kicking, and high RPM shifting. Designed for the enthusiast who pushes the limits of performance on their high powered vehicle and wants to maintain excellent pedal feel. The FX1000 Twin Disc is ideal for applications with large bell housings such as the Toyota 2JZ or the GM LS engines.

The cover assembly is machined from billet aluminum and is then Type 3 hard anodized. Our billet covers have roughly 25% more tensile strength than the competition’s cast unit. By focusing our ability on machining the strongest cover possible while maintaining minimal weight, we are basically able to eliminate any flex in the cover. Our billet covers see only .003" of flex where as a cast or stamped unit can see as much as .030" of flex. By eliminating this flex in the cover, the driver is able to operate the clutch much more consistently and confidently. All the movement being applied to the diaphragm of the clutch from the throwout bearing is used solely to engage and disengage the clutch and isn't wasted by the cover flexing first. The strength of our covers also results in greater clamping force over the same amount of area vs. a cast or stamped cover. This means our twin discs are easy to drive and have superior clamping force to make sure all the power your engine is making is being utilized.

Flywheels are made for each specific application in either aluminum or steel. Our aluminum flywheels are machined from billet 6061-T6 aluminum to meet SFI spec 1.2 for competition in NHRA, NDRA, IDRC, IHRA, SCCA and NASA. Aluminum flywheels are Type 3 hard coat anodized to ensure their durability and performance lasts. Each aluminum flywheel includes a replaceable insert. Steel flywheels are machined from 1045 billet cores and are then black oxide treated for rust prevention

Available Stages:

- “Street” (TD12S) – 1 sprung organic disc, and 1 organic rigid disc -- Tq Rating: 1,100 ft/lbs.

- “Race” (TD12R) – 1 sprung 6-puck ceramic disc, and 1 6-puck ceramic rigid disc -- Tq Rating: 2,000 ft/lbs.

The FX1200 Twin Disc Series is 12" (305mm) diameter assembly, which is designed for incredibly high torque output applications found in diesel trucks. The 1200 Series utilizes a strap driven plate design which allows for smooth engagement and minimal clutch chatter while still being able to withstand hard launches and heavy trailer pulling. The average weight of the entire system has been engineered to be roughly 10% lighter than the factory clutch in order to maintain minimal gear chatter in your NV4500, NV5600 or G56 transmission. The 1200 series Twin disc will accept one sprung disc creating a smoother engagement compared to two rigid discs.

The cover assembly is machined from billet aluminum and is then Type 3 hard anodized. Our billet covers have roughly 25% more tensile strength than the competition’s cast unit. By focusing our ability on machining the strongest cover possible while maintaining minimal weight, we are basically able to eliminate any flex in the cover. Our billet covers see only .003" of flex where as a cast or stamped unit can see as much as .030" of flex. By eliminating this flex in the cover, the driver is able to operate the clutch much more consistently and confidently. All the movement being applied to the diaphragm of the clutch from the throwout bearing is used solely to engage and disengage the clutch and isn't wasted by the cover flexing first. The strength of our covers also results in greater clamping force over the same amount of area vs. a cast or stamped cover. This means our twin discs are easy to drive and have superior clamping force to make sure all the power your engine is making is being utilized.

Steel flywheels are precision machined from 1045 billet cores and are then black oxide treated for rust prevention. Aluminum flywheels are available for diesel applications as well and are machined from billet 6061-T6 aluminum to meet SFI spec 1.2 for competition in NHRA, NDRA, IHRA, SCCA. Aluminum flywheels are Type 3 hard coat anodized to ensure their durability and performance lasts. Each aluminum flywheel includes a replaceable insert.