Most parts in stock and ready to ship. Orders fulfilled in 1-3 business days.

Get a free Clutch Masters shirt and the option of free ground shipping within the Continental US with purchases over $300.

Most parts in stock and ready to ship. Orders fulfilled in 1-3 business days.

Get a free Clutch Masters shirt and the option of free ground shipping within the Continental US with purchases over $300.

Clutch Masters performance flywheels are designed and tested to ensure the safety and quality of every flywheel. Years of R&D has given us the knowledge and firsthand experience to choose wisely the best material to manufacture high-quality aftermarket flywheels that will surpass your expectations. Depending on the application, most Clutch Masters flywheels are made from 6061 T6 Billet Aluminum, 1045 Billet Steel, or 4140 Billet Steel. Each one is SFI Certified, meeting performance standards for the automotive and motorsport industry.

A Dual Mass Flywheel (DMF) is a flywheel in two concentric parts or two facing flywheels stuck together with flexible compound to damp down transmitted vibration and gear rattle for the gear box. Many newer model vehicles now come standard with a factory DMF. Many times, enthusiasts choose to replace a DMF with a SMF and here is why:

*** Clutch Masters offers Aluminum or Steel single-mass flywheels depending on the application. We recommend you replace your DMF with a Steel SMF if the vehicle will be driven on the street since it will produce less noise and will be more pleasant to drive on the street compared to an Aluminum SMF. Aluminum flywheels are only recommended for race applications looking to have the least amount of weight as possible. By replacing a DMF with a SMF you may experience gear rattle and a vibration that may not be suitable for everyone. SMF may also reduce the life expectancy of a clutch kit depending on the application.

Replacing your OEM flywheel with a lightweight aftermarket flywheel may cause gear noise or a vibration that may not be suitable for everyone. The lighter the performance flywheel, the more gear noise will be produced. Depending on the application, Clutch Masters usually recommends Steel rather than Aluminum since the latter will cause more gear noise.

6061 Bilet Aluminum:

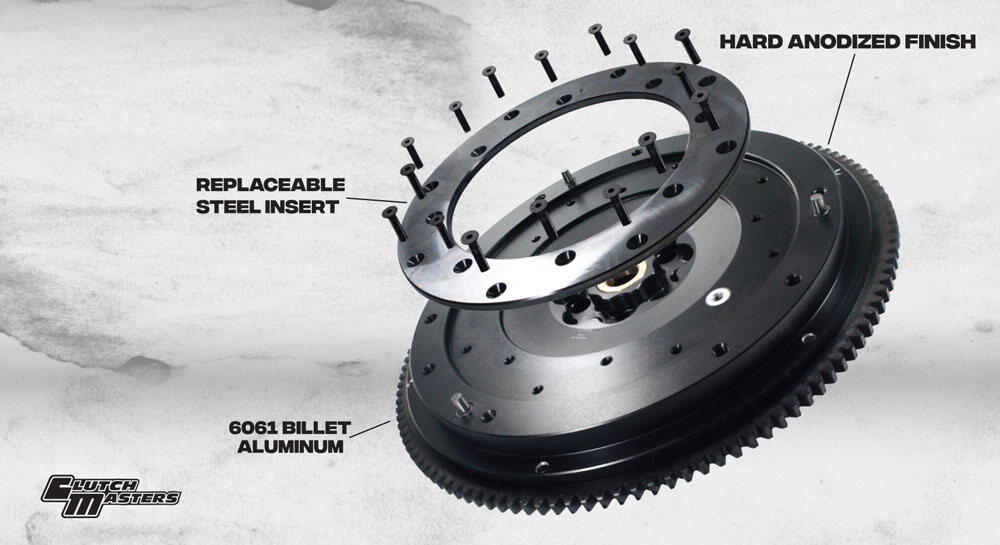

Clutch Masters’ aluminum flywheels are precision machined on our CNC machines to exact tolerances for a perfect fitment on your application. All aluminum flywheels are machined from a solid 6061 T6 billet. Our billets are sourced from US manufacturers and are guaranteed free of impurities or defects. Throughout the machining process every flywheel is checked to make sure the flywheel is built to spec and that all critical measurements are within tolerance. After the flywheels are machined they are Mil-Spec anodized in our in house, top of the line, anodizing system. Once anodized they receive final assembly with their replaceable steel insert being torqued down, pilot bearing installed (if applicable) and a thorough once over is given to the flywheel before it is packaged up and ready for your project! All aluminum flywheels come with a replaceable steel insert and are SFI certified for use in all sanctioned racing bodies.

4140 STEEL:

Clutch Masters’ steel flywheels are precision machined on our CNC machines to exact tolerances for a perfect fitment on your application. Our steel flywheels are machined from 1045 or 4140 billets that are sourced from US manufacturers and are guaranteed free of impurities or defects. Some of our very popular ultra-light steel twin disc flywheels used for racing are forged chromoly pieces that are then finished to exact tolerances. As our steel flywheels are being machined, a Clutch Masters craftsman continuously checks each flywheel throughout it’s build to make sure it has been machined to exact specifications and every critical measurement is within tolerance. All of our steel flywheels receive a black oxide coating to ensure they stay rust free for the life of the flywheel. After they are coated they are laser engraved with our logo and part number, boxed up and ready for your project! All steel flywheels are SFI certified for use in all sanctioned racing bodies.