Breaking in a Dual-Disc Clutch: A Step-by-Step Guide

Before you can experience the exceptional holding power and track-ready performance of your new high-performance dual-disc clutch, you must break in your new clutch properly. While a performance-focused clutch can take your vehicle’s performance to new heights, you don’t want to immediately overstress the components and risk causing damage.

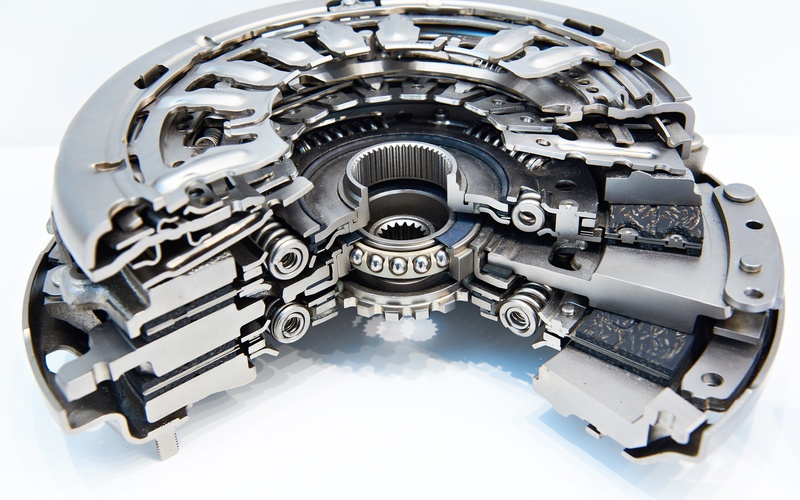

Unlike a single-disc clutch, a dual-disc clutch uses two friction surfaces for incredible clamping force, which requires a specific break-in procedure. Rushing this period can cause premature wear, slippage, and costly damage. Below, our guide will take you step-by-step through this important breaking-in process for a dual-disc clutch so you can maximize and protect your new performance investment.

Why the Break-In Period is Necessary

The break-in process, which many drivers and mechanics also call "bedding" a new clutch, serves several vital functions that directly affect your clutch's performance and durability. During manufacturing, the friction materials have tiny imperfections. A proper break-in gradually smooths these surfaces, creating the even contact pattern necessary for efficient power transfer.

If you don’t break in your clutch gradually and properly, it can cause significant problems in your vehicle. Typical issues from not bedding a new performance clutch include:

- Uneven Wear: This can cause grabbing, chattering, or inconsistent engagement. These issues hurt performance and cause permanent damage.

- Glazing: If the friction materials get too hot too quickly, they can "glaze over," creating a slick surface that drastically reduces holding power and causes slippage under load.

- Overheating: A gradual break-in allows the friction materials to cure properly and lets all the metal components adapt to heat cycles. A sudden blast of high temperature can cause warping, cracking, or other failures.

Professional racers know that a proper break-in for a new performance clutch is not optional. The patience shown during these first 500 miles pays off with consistent performance, lower maintenance costs, and a much longer service life for your clutch.

Pre-Break-In Preparation

Before breaking in your new double-disc clutch, you’ll need to gather the necessary tools and prepare your vehicle. First, inspect all clutch components before installation. Check the flywheel surface for any flaws and confirm you are using the correct bolt torque specifications for every part of the assembly. The precision engineering of a dual disc clutch demands careful attention to detail.

Next, verify your hydraulic system. Make sure the master and slave cylinders function correctly, the fluid level is adequate, and there is no air in the system. You must fix any hydraulic issues before you begin breaking in the clutch.

Finally, check your transmission fluid level and condition. Fresh fluid helps protect the internal components of your drivetrain during this critical period. Note your vehicle's current mileage to establish a baseline for tracking the break-in.

How To Break in a New Dual-Disc Clutch

Now that you and your vehicle are ready, it’s time to bed in the dual-disc clutch. Our guide will take you step-by-step through the breaking-in process of a dual-disc clutch that should last approximately 500 miles.

Phase 1: Initial Gentle Engagement

The goal of this first phase is to establish initial contact between the new friction surfaces. Start the engine and let it warm up to its normal operating temperature. With the parking brake on, press the brake pedal and slowly release the clutch pedal, allowing controlled engagement of the surfaces without shock load. Repeat this gentle engagement 5 to 10 times, ensuring the clutch cools down for a minute or two between repetitions.

Listen for any unusual noises that might indicate an installation issue, and confirm that the clutch engagement feels progressively smoother as the surfaces mate. Keep all inputs gentle, avoiding aggressive movements, and limit each engagement to a few seconds before fully disengaging for cooling. Monitor the clutch pedal feel for consistency and address any irregularities before proceeding further.

Phase 2: Low-Speed City Driving

In the second phase, use gentle city driving for frequent clutch engagements without building up excessive heat. Take short trips in stop-and-go traffic, focusing on smooth, deliberate clutch operation while keeping engine speeds below 3,000 RPM. Shift gradually and easily, and verify that the clutch fully disengages between gears. This regular starting and stopping helps create a uniform wear pattern.

During this phase, avoid steep hills, heavy traffic, and any situation requiring extensive clutch slipping. Pay attention to the clutch engagement, which should become smoother with a more predictable bite point. Continue this process for approximately 200-300 miles, gradually increasing trip length as performance stabilizes.

Phase 3: Gradual Load Increase

In this phase, steadily introduce moderate acceleration and higher engine speeds while managing temperature carefully. Incorporate gentle throttle input and brief periods of moderate acceleration, engaging without slippage or chattering. If slipping occurs, return to gentler driving.

Include some highway driving but avoid constant high speeds or aggressive acceleration, focusing on conditioning surfaces under varied loads. Over the next 100-150 miles of mixed driving, slowly increase performance demands while monitoring the clutch's behavior and temperature gauges.

Temperature Management

During the entire break-in process for your new clutch, temperature management is the priority. Dual disc clutches generate more heat than single disc units. Allow for proper cooling periods between driving sessions, especially in hot weather.

If your temperature gauge starts to climb, reduce your driving intensity and let the system cool down. Patience here prevents costly damage.

Final Inspection and Performance Validation

After about 500 total miles, your new clutch should be properly broken in now. However, your job is not over. Perform a final inspection to validate the results.

Check Fluids

Inspect all fluid levels and look for any signs of contamination or excessive wear. If fluid levels are below their minimums, it’s likely due to a leak somewhere in the system. Proper fluid levels are vital for optimal clutch performance and longevity.

Test Engagement

Test the clutch engagement in various situations, including cold starts, normal operating temperatures, and light acceleration. The pedal feel should remain consistent and positive throughout these tests.

Validate Performance

Under load, the clutch engagement should feel solid, with no slippage during acceleration. A properly broken-in clutch will show far superior holding power than the stock unit. If you notice any slippage, it could indicate an incomplete break-in process or a potential installation issue.

Maximize Your Performance Investment With Clutch Masters

Following the proper break-in procedure transforms your clutch from a box of parts into a reliable, high-performance component. The patience during these first 500 miles is a small price to pay for consistent operation, minimal maintenance, and the full power-transfer efficiency you expect.

Unlock the full potential of your Clutch Masters dual disc clutch, a true piece of racing technology. Proper installation and diligent break-in aren't just recommendations—they are necessities to maximize performance, verify longevity, and protect your Clutch Masters warranty. Treat this critical break-in period as the final tuning for your high-performance upgrade. Don't compromise your investment; follow the Clutch Masters guidelines to experience the full power and precision you expect.