Does the Clutch & Flywheel Need To Be Upgraded at Same Time?

When upgrading drivetrain components, performance enthusiasts often face the question: Should I upgrade the clutch and flywheel together? This is especially important when pushing your vehicle to its limits on the track or maximizing power transmission efficiency. In this guide, we’ll break down what vehicle owners need to know about their clutch and flywheel, and whether they need to upgrade them at the same time.

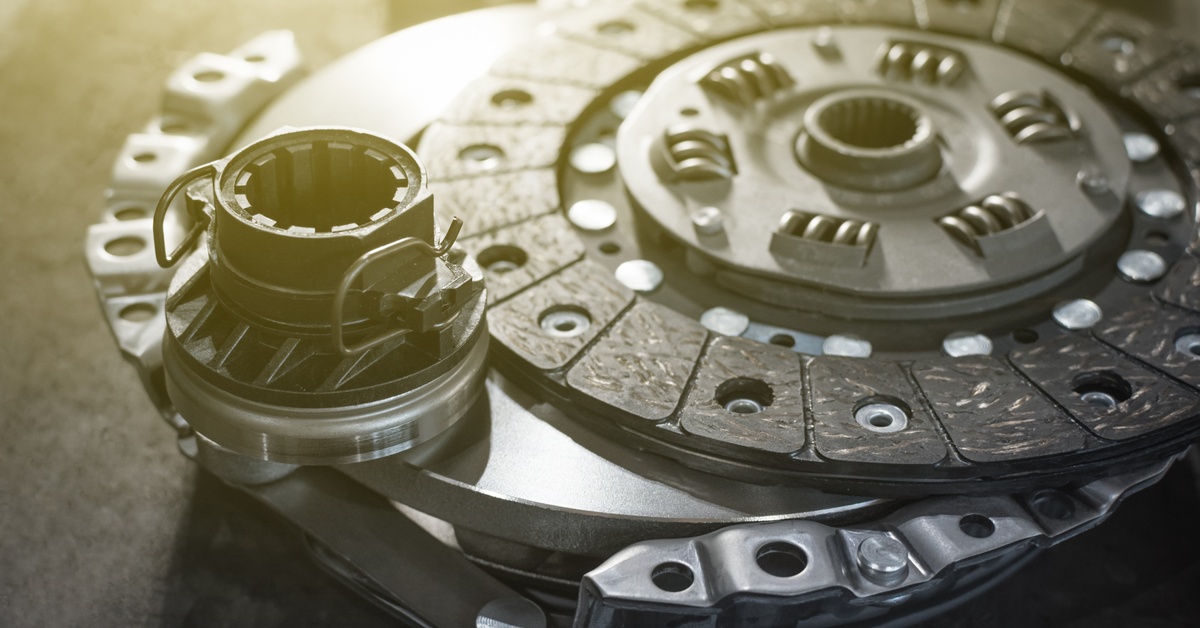

Understanding the Clutch and Flywheel System

The clutch serves as the critical link between your engine's rotational power and the transmission system. This component engages and disengages the connection, allowing smooth power transfer while enabling gear changes and engine idling without stalling. High-performance clutches feature premium friction materials and stronger pressure plates to handle increased torque loads without slipping.

Your flywheel functions as both an energy storage device and a mounting surface for the clutch assembly. The flywheel stores rotational energy during power strokes and releases this energy during non-power strokes, smoothing engine operation and maintaining consistent rpm. The flywheel's mass characteristics directly influence your vehicle's acceleration response and engine behavior. Lighter flywheels reduce rotational inertia, allowing faster engine rev changes, while heavier flywheels provide smoother engagement and better low-end torque multiplication but slower throttle response.

Factors Driving Upgrade Decisions

Whether you want to upgrade your vehicle’s flywheel or clutch will depend on various factors. You may want to maximize the performance of your car, or you need to replace visibly worn components.

Power Increases

The most common catalyst for a clutch and flywheel upgrade is a power increase. While stock components can handle factory power levels with a reasonable safety margin, engine modifications will quickly push past these limits. Adding a turbocharger or supercharger, or making internal engine modifications, can easily double or triple torque output, overwhelming the factory clutch's capacity.

Wear and Tear

Visible wear patterns are clear indicators that an upgrade is necessary. Telltale signs include deterioration of the clutch disc's friction material, scoring on the flywheel's surface, or warping of the pressure plate. However, wear rarely affects both components equally, which often creates a timing dilemma for enthusiasts deciding when to upgrade.

Performance Goals

Your specific performance objectives will heavily influence your upgrade strategy. For track-focused builds, the priority is rapid engagement, superior heat dissipation, and consistent performance under extreme stress. In contrast, street-performance applications must balance these aggressive characteristics with the demands of daily drivability, which requires different component specifications.

Racing Applications

Motorsport applications require components built for the unique demands of competition. Drag racing setups, for example, need maximum holding power and explosive engagement. Road racing, on the other hand, prioritizes heat management and consistent performance over long, grueling sessions. These needs typically demand a fully matched component system rather than piecemeal upgrades.

Do I Need to Upgrade My Clutch and Flywheel Simultaneously?

Whether you need to upgrade the clutch and flywheel of your vehicle at the same time will depend, but it’s not a requirement. Upgrading both the clutch and flywheel at the same time isn’t always necessary, but it can often yield the best results depending on your performance goals. The clutch and flywheel work in tandem, and replacing only one component may limit the overall improvement you experience.

For example, a lightweight flywheel can enhance throttle response and reduce rotational mass, providing significant advantages in racing scenarios. However, if your existing flywheel is in excellent condition and compatible with your new clutch, a standalone clutch upgrade may suffice for modest performance gains.

Advantages of Simultaneous Upgrades

Simultaneously upgrading your vehicle with a performance clutch and flywheel kit will provide many advantages. The matched performance characteristics, complementary design philosophies, and installation precision all make it worthwhile for those who want to maximize performance.

Matched Performance Characteristics

The primary benefit of upgrading the clutch and flywheel simultaneously lies in their equal performance properties. Manufacturers engineer performance clutch systems around specific flywheel specifications, such as mass, friction surface area, and thermal properties. This design guarantees optimal power transfer efficiency and enhances component longevity.

Complementary Design Philosophies

When the clutch and flywheel share complementary design features, they achieve optimal functionality. Performance flywheels incorporate special surface treatments or materials that require matching clutch disc compounds for maximum effectiveness. For example, single-mass flywheels eliminate dual-mass damping systems, necessitating clutches for direct drivetrain connection without intermediate cushioning.

Labor Savings

Upgrading both components simultaneously offers significant economic benefits by reducing labor costs. Accessing the clutch assembly and removing the transmission are labor-intensive tasks. Replacing both the clutch and flywheel at the same time minimizes overall labor hours, as professional installation typically takes between eight and twelve hours.

Installation Precision

Installing a new clutch and flywheel together allows technicians to balance and align the components as a complete system. This verifies proper engagement geometry and eliminates potential interference issues. Combining flywheel resurfacing or replacement with clutch installation significantly reduces the likelihood of post-installation adjustments or warranty claims.

Consistent Performance

Matched component specifications ensure consistent performance and break-in characteristics. Installing new clutches and flywheels together establishes their operating parameters in unison, creating a consistent engagement feel and wear pattern. This synchronization prevents the adaptation challenges that occur when new components paired with worn counterparts.

Making Your Upgrade Decision

When deciding if a dual upgrade of your clutch and flywheel is necessary for your vehicle, there are multiple factors to consider. You should first assess your performance objects and consult with professionals for expert advice.

Assess Your Performance Objectives and Usage Patterns

Before committing to upgrade strategies, evaluate your specific performance goals and usage habits. Track-focused builds benefit most from simultaneous upgrades, as the performance gains and reliability improvements justify the additional investment. For street-performance applications, individual component upgrades spread across maintenance intervals may achieve satisfactory results.

Consult with Professionals for Expert Recommendations

Work with professional mechanics or performance specialists who understand your vehicle and its intended use. These experts can recommend component combinations that provide optimal performance while avoiding compatibility issues or unnecessary over-specification. Their experience with similar builds offers valuable insights into long-term reliability and maintenance requirements.

Evaluate Component Condition Through Inspection

Professionally inspect your current components instead of assuming anything. For example, flywheels with minimal wear may deliver years of additional service with a new clutch, whereas you should replace severely worn units immediately, regardless of clutch condition. A professional assessment helps prevent unnecessary replacements while ensuring safety and reliability.

Maximize Your Investment with Clutch Masters

Optimizing your clutch and flywheel components hinges on your performance goals, budget, and the condition of your current components. For racing applications, matched component systems are best at delivering unparalleled performance and reliability under extreme loads. Street-performance builds, however, demand a nuanced balance between power gains and daily drivability.

Professional consultation is indispensable for maximizing performance investments and averting expensive compatibility issues. Our expert guidance ensures optimal component selection and installation. Contact Clutch Masters Industries today to tailor a bespoke component recommendation for your vehicle platform and ambitious racing objectives.