What You Should Know About Basic Car Clutch Anatomy

For any serious driver, understanding the intricate machinery that powers your vehicle is not just a matter of curiosity—it's a necessity for achieving peak performance. The clutch system, a critical component in manual transmission vehicles, is central to controlling power from the engine to the wheels.

The car clutch engages and disengages power transmission from the engine's crankshaft to the transmission. Its primary function is to allow the driver to smoothly change gears and to stop the vehicle without stalling the engine. In this guide, we’ll explain everything you should know about basic car clutch anatomy, maintenance, and more.

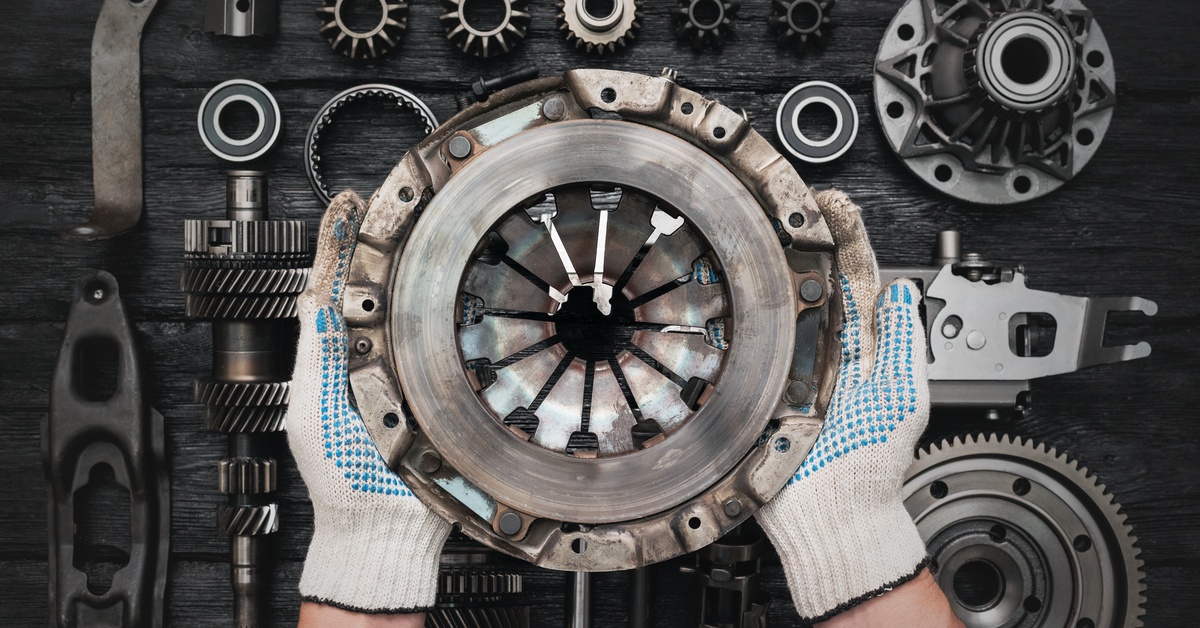

Key Components of a Car Clutch

A clutch system is a sophisticated assembly of interconnected parts, each playing a vital role. Mastery of this system begins with an in-depth understanding of each component.

Clutch Disc

The clutch disc is the heart of the system, acting as the friction surface that connects the engine to the transmission. It is a circular plate with a high-friction material covering, similar to brake pads. This disc is securely fit to the transmission's input shaft via a spline, allowing it to slide back and forth while rotating with the shaft.

The quality of the friction material is integral for performance, determining the clutch's ability to handle high torque and dissipate heat without fading or failing. Clutch Masters utilizes proprietary friction formulas for superior grip and longevity, ensuring your vehicle performs consistently under extreme racing conditions.

Pressure Plate

The pressure plate is a spring-loaded metal plate that bolts to the flywheel. It applies consistent and powerful pressure to the clutch disc, clamping it firmly against the flywheel. This clamping force is what enables the transfer of engine torque to the transmission.

The pressure plate assembly contains a diaphragm spring or a coil spring that provides the necessary force. High-performance pressure plates, like those featuring Clutch Masters' Hi-Leverage™ technology, increase clamping force significantly without a corresponding increase in pedal effort, providing greater holding power for modified engines.

Flywheel

The flywheel is a heavy, rotating disc that bolts directly to the engine's crankshaft. It serves several crucial functions. First, it provides a smooth, flat surface for the clutch disc to engage with. Second, its inertia smooths out the power pulses from the engine's combustion cycles for a more stable rotation.

In performance applications, lightweight aluminum flywheels reduce rotational inertia, allowing the engine to rev more quickly and improving acceleration. The flywheel's surface must be perfectly flat and true for proper clutch engagement and to prevent chatter.

Release Bearing

Also known as the throw-out bearing, the release bearing is a critical component for disengaging the clutch. It is a bearing assembly that rides along the transmission's input shaft sleeve. When you press the clutch pedal, the release bearing moves forward and contacts the fingers of the pressure plate's diaphragm spring.

This action retracts the pressure plate from the clutch disc, interrupting the flow of power and allowing for a gear change. The durability and smooth operation of this bearing are essential for reliable clutch performance.

Clutch Fork

The clutch fork is a lever that pivots to move the release bearing. One end of the fork holds the release bearing, while the other connects to the clutch actuation system. When the driver presses the clutch pedal, the fork pivots and pushes the release bearing against the pressure plate.

The fork acts as a force multiplier, converting the driver's pedal input into the substantial force necessary to disengage the clutch. Its design and material strength are crucial for withstanding the repeated stresses of clutch operation.

Clutch Cable or Hydraulic System

The force from the driver's foot on the clutch pedal transmits to the clutch fork through either a mechanical cable or a hydraulic system. A clutch cable is a simple, direct link, but it can stretch and wear over time.

A hydraulic system, which is more common in modern performance vehicles, uses a master cylinder and a slave cylinder connected by a fluid-filled line. This system provides a smoother, more consistent pedal feel and self-adjusts for clutch wear. Hydraulic systems offer superior precision and reliability, which are vital for competitive driving.

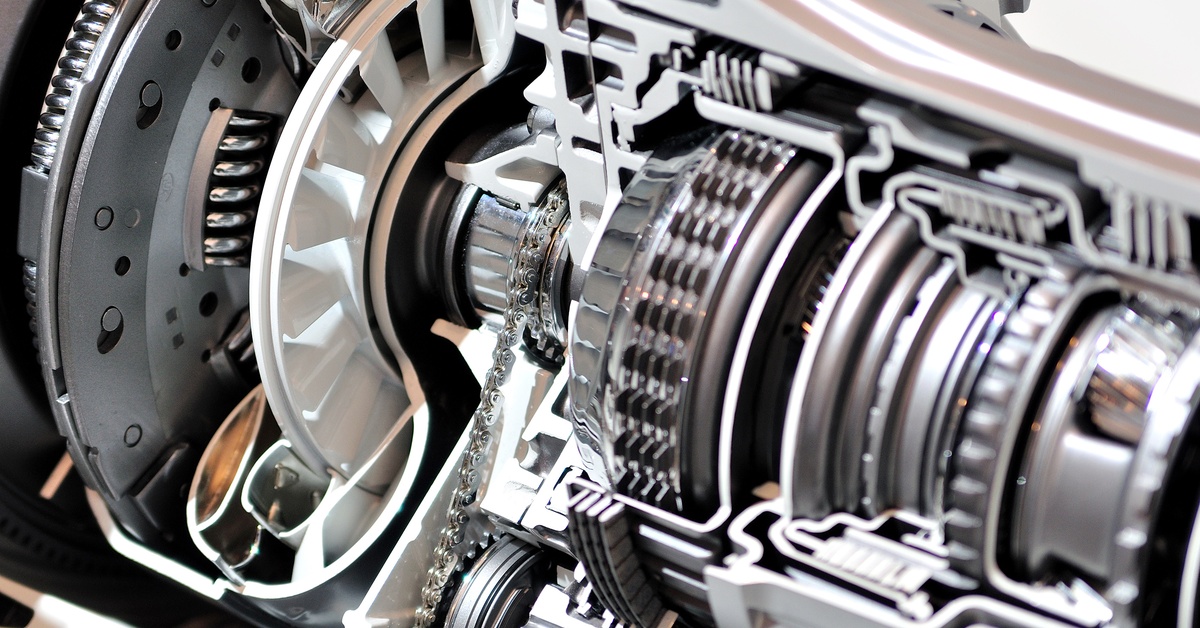

Single-Disc vs. Double-Disc Clutch Systems

Standard road vehicles typically have a single-disc clutch system, which is sufficient for stock power levels. However, for high-horsepower race cars, a single disc may not provide enough surface area to handle the immense torque without slipping. This is where multi-disc clutch systems, such as a double-disc clutch, become essential.

A twin-disc clutch uses two discs and a floater plate between them, effectively doubling the friction surface area within the same diameter. This creates a significantly higher torque capacity, faster shifting, and improved durability, making it the preferred choice for serious racing applications.

How the Clutch System Works

Now that you know about basic car clutch anatomy, we can examine how the system functions in totality. The operation of the clutch system is a precise sequence of mechanical actions. When the clutch engages, the pressure plate's springs forcefully clamp the clutch disc against the flywheel. This creates a solid connection, allowing the engine's power to flow through the clutch disc to the transmission's input shaft, and ultimately to the wheels.

When you press the clutch pedal to disengage the clutch, the clutch fork pushes the release bearing against the diaphragm spring of the pressure plate. This releases the clamping force on the clutch disc. This creates a small air gap between the disc, flywheel, and pressure plate, which breaks the connection to the engine. The transmission input shaft is now free from the engine's rotation, allowing you to shift gears smoothly without grinding.

Common Clutch Problems and Symptoms

Recognizing the signs of a failing clutch can save you from catastrophic failure on the track. Common issues include clutch slipping, where the engine RPMs increase without a corresponding increase in vehicle speed, indicating worn friction material. Clutch drag occurs when the clutch fails to fully disengage, resulting in grinding gears.

A contaminated or warped clutch disc or flywheel can cause clutch chatter, which is a stuttering or vibration upon engagement. A noisy clutch can indicate a bad release bearing, while a hard or sticking pedal may signal problems with the hydraulic system or pressure plate.

Clutch Maintenance and Longevity

Proper driving technique is the most effective way to extend the life of your clutch. Avoid "riding" the clutch pedal and ensure quick, decisive shifts. Regular inspections of hydraulic fluid and leak checks can prevent system failures.

Eventually, however, all clutches wear out. When it's time for a replacement, upgrading to a high-performance Clutch Masters system is an investment in your vehicle's reliability and performance.

Elevate Your Performance With Clutch Masters

A thorough understanding of your clutch system is the foundation of high-performance driving. Each component—from the flywheel to the release bearing—plays a critical role in controlling your engine's power. By understanding how these parts work together and identifying signs of wear, you can keep your vehicle in peak condition and make strategic upgrades.

Explore the Clutch Masters lineup of racing-ready clutch systems and flywheels to find the precision-engineered solution that will unlock your vehicle's true potential. Engineered for excellence and built for champions, our products deliver unmatched reliability and holding power to dominate the competition.