How Your Hydraulic Clutch Delay Valve Works: An Overview

For many car enthusiasts, upgrading their vehicle’s hydraulic clutch assembly is essential to achieving the ultimate driving experience. Understanding the core components and how they function is crucial for maintaining a high-performance manual transmission. The clutch delay valve is a vital but often overlooked piece of the hydraulic clutch system. Below is an overview of your hydraulic clutch system and clutch delay valve, including its parts, how it works, and why you should consider a Clutch Masters flow control valve for your vehicle.

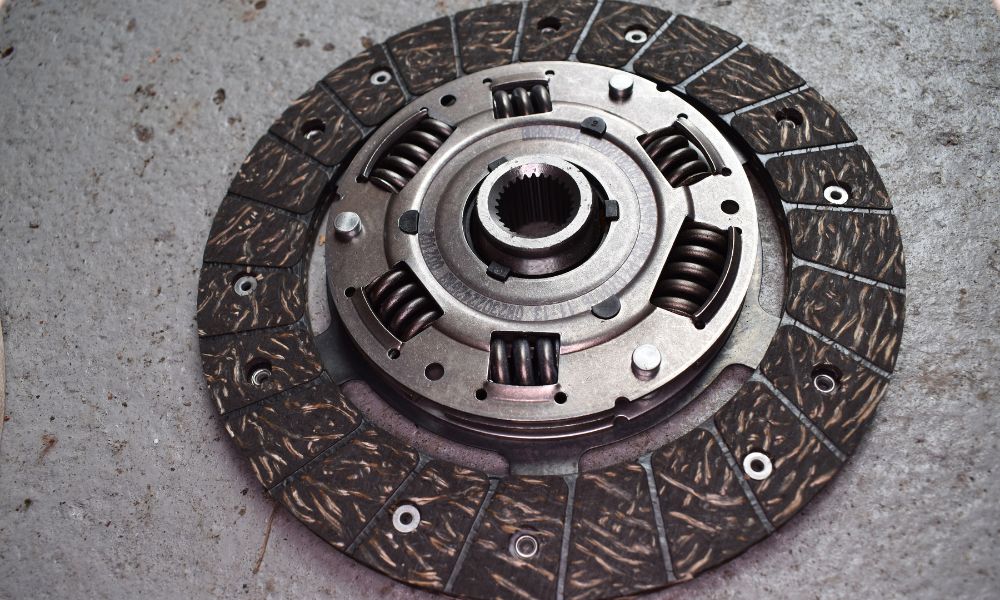

How Your Hydraulic Clutch Works

To understand the role of a hydraulic clutch delay valve, we first need to understand how a hydraulic clutch system works. A typical manual transmission vehicle will have three main components: the clutch pedal, the slave cylinder, and the master cylinder. Pressing down on the clutch pedal engages with the master cylinder, which then pushes hydraulic fluid through a series of lines to the slave cylinder. The fluid flow puts pressure on a piston in the slave cylinder, disengaging the clutch and allowing for smoother gear shifting.

What Is a Clutch Delay Valve?

A hydraulic clutch delay valve controls the speed of the hydraulic fluid within a hydraulic clutch assembly. It does this by regulating the flow or pressure of the fluid to ensure smooth and precise engagement and disengagement of the clutch. This regulation results in consistent gear shifting and improved driver control.

Why Does a Hydraulic Clutch Need a Clutch Delay Valve?

In a manual transmission, the clutch assembly works under tremendous pressure whenever the gears change. A hydraulic clutch relies on hydraulic fluid to transmit this pressure from the clutch pedal to the clutch mechanism. The clutch delay valve ensures the appropriate amount of pressure is applied, allowing the clutch to engage and disengage properly while preventing potential damage to the system.

Common Issues That Can Arise and How To Address Them

Like any other automotive component, clutch delay valves can experience issues over time, ultimately affecting your vehicle’s performance.

Leak/Loss of Pressure

One common issue that may arise in a clutch delay valve is the leak or loss of pressure. This issue can manifest in various ways, such as a soft or spongy clutch pedal, difficulty in shifting gears, or the clutch failing to disengage. The cause of these symptoms can often be traced back to a leak in the hydraulic system, leading to a drop in fluid pressure. An effective solution to this issue is first visually to inspect the hydraulic system for any signs of leaks. This includes checking the master and slave cylinder, the hydraulic lines, and the clutch delay valve.

Sticking Valves

Another common issue that can occur with clutch delay valves is sticking valves. This problem is often signified by the clutch pedal becoming difficult to depress or slow to return to its resting position. The root cause can be the build-up of debris or the wear and tear of the valve components over time, causing the valve to stick in the open or closed position.

Addressing this involves diagnosing the problem by visually inspecting the valve for signs of excessive wear or dirt accumulation. If confirmed, a thorough cleaning or replacement of the valve may be required.

Contamination or Blockage in System

Contamination or blockage in the system can also plague clutch delay valves. These issues can result from the accumulation of dirt, dust, or other contaminants within the hydraulic fluid, leading to a blockage that disrupts the smooth flow of fluid. Symptoms can include jerky clutch action, difficulty in gear shifting, or an unresponsive clutch pedal.

Addressing this problem typically requires a complete system flush to remove the contaminated fluid and any blockages. Replacing the compromised fluid with fresh, high-quality hydraulic fluid can restore the system’s functionality.

High-Performance Problems With Control Delay Valves

For experienced and skilled drivers seeking maximum performance, the control delay valve can cause more harm than good. Since it restricts fluid flow to the clutch, it can result in premature wear and tear. The valve is meant to slow down the engagement of the clutch, but this can lead to excessive slipping and overheating, especially during aggressive driving, and drivers often complain of the lack of feel with the clutch because of the delay valve.

For high-performance drivers who demand quick and precise shifts, a delay in clutch engagement can be frustrating and impede their driving experience. To achieve optimal performance, it is recommended for high-performance drivers to remove the clutch delay valve. This will provide a direct and immediate connection between the engine and transmission, allowing for quicker shifts and an improved overall driving experience.

The Clutch Masters Flow Control Valve

For drivers looking to replace their clutch delay valve with something more performance-focused, Clutch Masters Industries offers the aftermarket flow control valve. The Clutch Masters flow control valve works similarly to a clutch delay valve but is much simpler and is more suited for high-performance cars.

The flow control valve reduces the driveline shock loads from extreme performance demands and aggressive clutch use. The flow control valve allows for faintly more slippage during engagement through control of the return flow of the hydraulic fluid. In regular driving conditions, the valve doesn’t restrict hydraulic fluid flow during disengagement, so the clutch pedal release and engagement operate and feel normal to drivers. The Clutch Masters flow control valve offers increased capability in high-stress situations without sacrificing comfort and ease during normal conditions.

Maintenance Tips for Your Clutch’s Clutch Delay Valve

Routine Inspections and Fluid Changes

Regular system inspections and fluid changes are essential to ensure your clutch delay valve and entire clutch assembly operate optimally. If a leak or contamination is detected early on, it can be addressed before it leads to more significant issues.

Use High-Quality Hydraulic Fluid

High-quality hydraulic fluid is crucial for your clutch delay valve to function properly. Lower-quality fluids may contain impurities that can lead to contamination and blockages within the system, affecting performance.

Cleaning and Lubricating Parts

Periodically cleaning and lubricating the valve components can help maintain functionality and prevent issues such as sticking valves. This involves removing dirt or debris from the valve and applying a suitable lubricant to ensure smooth movement. Be sure to use appropriate lubricants designed for use with hydraulic systems.

Replace Your Hydraulic Clutch or Parts With Clutch Masters Industries

We hope our overview of how your hydraulic clutch delay valve works and its components gives you a better understanding of your vehicle and its clutch assembly. This component is pivotal in ensuring smooth gear shifting, enhancing driver control, and preventing potential damage to your clutch system. Regular maintenance and use of quality parts ensure the longevity of your hydraulic clutch system and elevate your driving experience.

If your clutch delay valve is causing problems in high-performance driving situations, consider a flow control valve from Clutch Masters Industries to maximize the performance potential of your vehicle. At Clutch Masters, we have a wide selection of hydraulic clutches for sale and aftermarket flow control valves. Browse our inventory and don’t hesitate to contact our staff with any questions about hydraulic clutches or flow control valves.