Dual-Mass vs. Single-Mass Flywheel: What’s the Difference?

The flywheel is a critical component hidden within the bell housing that too many drivers overlook. It does its job quietly until you start seeking faster lap times or more responsive shifts. When exploring aftermarket upgrades, you face a crucial decision: stay with the factory dual-mass flywheel (DMF) or convert to a single-mass flywheel (SMF). This choice impacts everything from acceleration and throttle response to the overall feel and sound of your vehicle.

Understanding the mechanical distinctions between these two designs is essential for anyone serious about vehicle performance. It's not just about swapping parts; it’s about engineering your ride to match your driving style. Whether you're chasing seconds on the track or building a more engaging street machine, this guide will compare dual-mass and single-mass flywheels and outline their differences.

What is a Flywheel?

Before comparing dual-mass and single-mass designs, it's important to understand a flywheel's primary role. A flywheel is a heavy, weighted disc that attaches to the engine's crankshaft. Its main job is to store rotational energy. An internal combustion engine delivers power in pulses as each cylinder fires, creating a naturally jerky power delivery. The flywheel's inertia smooths out these pulses, ensuring the crankshaft spins at a more constant speed between combustion strokes.

Beyond this, the flywheel provides the friction surface for the clutch disc. When you engage the clutch, the disc clamps against the flywheel, transferring torque from the engine to the transmission. The flywheel's weight, material, and design dictate how quickly the engine revs, how easily it might stall, and the transmission of vibration into the cabin.

The Dual-Mass Flywheel

Most modern manual transmission vehicles leave the factory with a dual-mass flywheel. Manufacturers choose this design primarily for comfort and refinement, catering to the average driver who prioritizes a quiet, vibration-free ride.

How a DMF Works

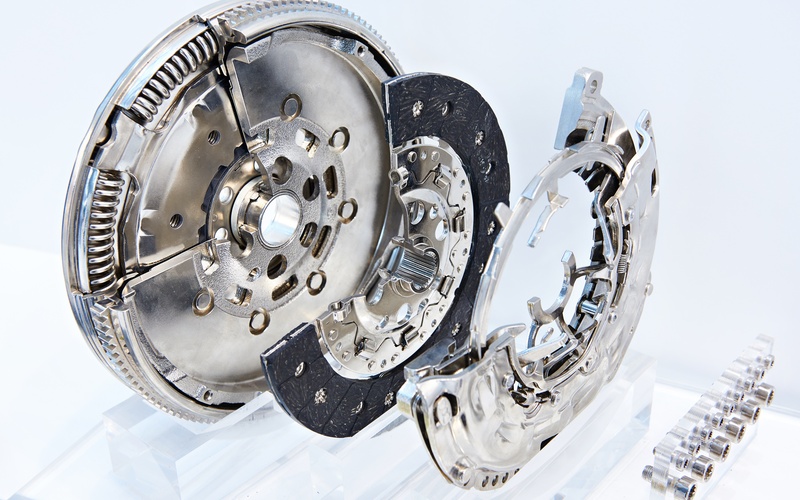

A dual-mass flywheel is effectively two flywheels that a sophisticated damping system connects. The primary mass bolts to the crankshaft, while the secondary mass attaches to the transmission. In between, a network of powerful springs and flexible components absorbs torsional vibrations from the engine.

When the engine fires, these internal dampers act as a buffer, soaking up the shock before it can reach the transmission. This allows the two masses to rotate slightly independently of one another, isolating the gearbox from harsh power pulses. The result is protection against gear rattle, and the driver feels significantly less noise, vibration, and harshness (NVH).

Pros and Cons of a DMF

The primary advantage of a DMF is refinement. It excels at damping engine vibration and driveline noise, creating a smooth and quiet driving experience. By absorbing torsional spikes, it also protects transmission components from premature wear and makes low-RPM driving feel less jerky.

However, this comfort comes at a cost. DMFs are complex, with many moving parts that wear out. The internal springs fatigue over time, leading to failure and requiring an expensive replacement. Unlike simpler designs, drivers cannot resurface a DMF; they must replace the entire unit.

Furthermore, DMFs are very heavy, often weighing over 30 pounds. This significant rotating mass creates inertia that slows engine response, causing sluggish revs and the frustrating "rev hang" between shifts. For the performance enthusiast, this dulls the driving experience.

The Single-Mass Flywheel

The single-mass flywheel is the performance upgrade that high-performance drivers who want a more durable and cost-effective solution desire. Also known as lightweight flywheels, their design embraces simplicity and raw performance over the isolated comfort of a DMF.

How an SMF Works

An SMF is a solid, single piece of metal, typically featuring billet steel or aluminum. It bolts directly to the crankshaft and provides a rigid friction surface for the clutch. There are no internal springs or complex damping mechanisms.

Instead of isolating vibrations within the flywheel, an SMF system relies on the springs built into the hub of the clutch disc to absorb some of the shock during engagement. These flywheels have a simple philosophy: reduce complexity and rotating mass to unlock engine performance.

Pros and Cons of an SMF

The most immediate benefit of converting to an SMF is durability. With no moving parts to fail, a quality SMF can last the lifetime of the vehicle. If the friction surface wears down from regular use, drivers can typically resurface it instead of replacing it completely—making it a more economical long-term choice.

The performance gains are equally significant. SMFs are much lighter than their dual-mass counterparts, reducing the rotational inertia the engine must overcome. This results in a much faster-revving engine, sharper throttle response, and quicker rev drops for rapid gear changes. This responsiveness transforms the car's character, making it feel more alive and connected to the driver.

The main trade-off is an increase in NVH. Without the heavy damping of a DMF, transmission gear rattle may become audible, especially at idle with the clutch out. Drivers may also feel more engine vibrations. This mechanical feedback is welcome for performance enthusiasts, but may not be ideal for the more casual, everyday driver.

Choosing the Right Flywheel for Your Build

Now that we understand the differences between a dual-mass and single-mass flywheel, which is right for you and your car? The correct flywheel depends entirely on your vehicle's purpose and your performance goals. There is no single "best" option—only the right tool for the job.

For the Track or Spirited Driving

If you are building a dedicated track car or a weekend warrior, converting to an SMF is a clear choice. The enhanced throttle response and reliability under high-RPM abuse are invaluable on the circuit.

Aluminum SMF is ideal for racing applications where every ounce counts, offering the lowest weight for the fastest revs, though it comes with greater gear noise and requires a more aggressive driving style for smooth launches. For high-performance street cars that double as daily drivers, a billet steel SMF strikes the perfect balance. Lighter than a stock DMF, it remains drivable in traffic while dampening more vibration than aluminum, making it a great compromise between performance and everyday usability.

For the Daily Commuter

If your priority is a quiet, comfortable ride for daily commuting and you rarely drive aggressively, sticking with the OEM Dual-Mass Flywheel is a reasonable choice. It will maintain factory levels of refinement, but drivers should understand the higher replacement cost when it eventually wears out.

Make the Shift to Precision Performance

The flywheel is at the heart of your driving experience, dictating how your vehicle responds to every command. While a factory DMF provides a cushion of comfort, it often masks your engine's true potential. Upgrading to a precision-engineered SMF unlocks a new level of reliability, quicker acceleration, and a more engaging drive.

At Clutch Masters, we engineer our flywheels to surpass expectations. Our 6061 T6 Billet Aluminum flywheels provide maximum weight reduction for race applications, while our 4140 Billet Steel flywheels offer the perfect blend of street-friendly inertia and proven durability. When you are ready to take control of your vehicle’s performance, a high-quality SMF is not just a repair—it's a transformation. Experience the difference in every shift, every rev, and every corner.