4 Benefits of Using Steel Braided Clutch Lines

Every detail matters when improving your vehicle’s performance and reliability—right down to the clutch line. Too often, DIY mechanics and clutch users overlook this component’s effect on smooth and consistent performance. If you’re still relying on factory-installed rubber clutch lines, you may be limiting your vehicle’s full potential.

Steel braided clutch lines combine durability, precision, and long-term performance. This blog will help you understand the role clutch lines play in a vehicle’s performance, the many benefits of using steel braided clutch lines, and why they’re effective. This upgrade offers many benefits for your vehicle, from greater durability to a better pedal feel.

Understanding the Role of Clutch Lines in a Vehicle

Before we get into the nitty-gritty of steel braided clutch lines and their advantages, it’s important to understand what clutch lines do for your vehicle in the first place. They transmit hydraulic pressure from the clutch master cylinder to the slave cylinder. The pressure engagement allows you to change gears smoothly and efficiently.

Your vehicle’s performance, pedal responsiveness, and driving feel hinge on the quality and condition of clutch lines. Unfortunately, factory clutch lines degrade over time due to heat, pressure, and environmental factors. These factors compromise their ability to perform effectively. This is where steel braided clutch lines come in as a superior alternative, offering a host of performance benefits.

How Steel Braided Clutch Lines Enhance Your Vehicle

Using steel braided clutch lines instead of rubber ones offers many benefits. Whether you’re looking to enhance your track car for competitive racing or you want a smoother driving experience for your everyday vehicle, steel braided clutch lines are excellent investments.

1. Enhanced Durability – Comparing Steel to Rubber

Rubber clutch lines may do the job when your vehicle is brand new, but they are far from a permanent solution. Over time, rubber lines are prone to expanding, cracking, and weakening under pressure, particularly in vehicles that are exposed to high temperatures or dynamic driving conditions. Degradation leads to inconsistent performance and potential failure.

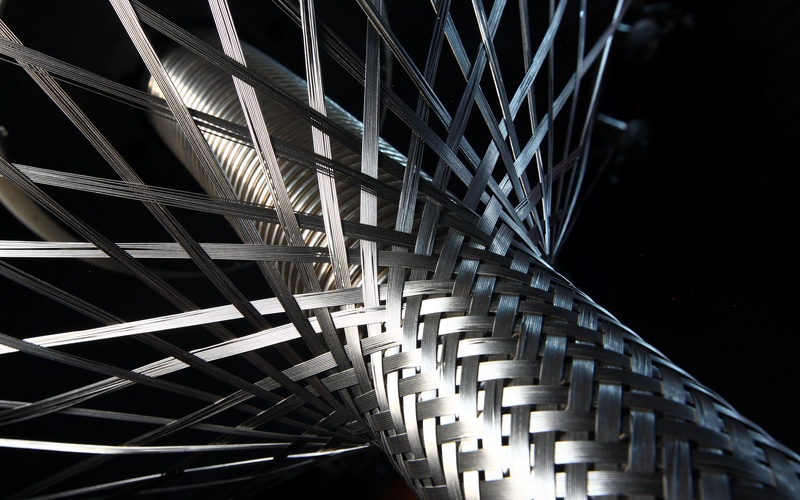

Steel braided clutch lines, on the other hand, feature superior engineering for greater durability. These lines contain a layer of stainless steel braided mesh surrounding the inner Teflon core, so the lines can withstand extreme pressures and repetitive use without deforming. Steel doesn’t weaken over time. Whether you’re navigating stop-and-go traffic or putting your clutch to the test on the track, steel braided clutch lines can handle the demands of everyday and high-performance driving.

2. Improved Pedal Feel – Eliminating Sponginess

Have you noticed a soft, spongy feeling while pressing the clutch pedal? This issue is especially common in old manual vehicles with worn-out rubber lines. Over time, the rubber can expand slightly when applying hydraulic pressure, preventing consistent fluid delivery to the clutch master and slave cylinders. The result is a soft pedal feel that can make gear shifts less satisfying and more inconsistent.

Steel braided clutch lines eliminate this problem. The stainless steel braiding prevents expansion under pressure, delivering a firmer and more responsive pedal feel. It’s an instant upgrade to the tactile feedback every manual driver craves. Increased pedal precision is a game-changer for drivers seeking a more reliable and enjoyable driving experience.

3. Quick Installation – Maintaining Factory Lines

One concern many drivers have when considering mods is the complexity of installation. Fortunately, a benefit of using steel braided clutch lines is they’re easy to install. They integrate seamlessly with a vehicle’s existing factory hard lines, requiring minimal effort to install.

Upgrading to a steel braided clutch line doesn’t require hours of fiddling under the hood or a trip to the shop. With basic tools and some hydraulic fluid for bleeding, most DIYers can complete this upgrade with ease. The compatibility with your vehicle’s factory setup also guarantees a clean, professional finish without altering existing hardlines.

4. Hydraulic System Efficiency – Supporting Optimal Performance

Optimizing the hydraulic clutch system is key to achieving peak performance, both in terms of reliability and responsiveness. Unfortunately, aging rubber lines can introduce inefficiencies over time, including sluggish fluid delivery and inconsistent pressure. Unchecked issues can accelerate wear on your clutch system and reduce drivability.

Steel braided clutch lines offer a boost in fluid transfer efficiency. Because they resist expansion and maintain their structural integrity under extreme conditions, they deliver consistent and reliable hydraulic pressure to the clutch components. This translates into smoother gear transitions, reduced wear on the system, and a longer lifespan for clutch parts.

Finding Braided Clutch Lines: What To Know

If you’ve decided that steel braided clutch lines are best for your vehicle, you need to understand what you’re looking for. When shopping for braided clutch lines for your car, focus on quality, compatibility, and durability. Look for high-grade stainless steel clutch lines with maximum resistance to wear, corrosion, and intense pressure.

Precision and fit are also essential to think about—verify that the clutch lines fit your vehicle’s make and model for seamless installation and optimal performance. Additionally, consider clutch lines that meet or exceed industry safety standards, as they offer more reliability under demanding conditions. At Clutch Masters Industries, we have a wide range of hydraulic clutch kits with stainless steel braided clutch lines for all sorts of vehicles.

Installing Steel Braided Clutch Lines: Bleeding the Clutch System

Bleeding the clutch system is a critical step after installing steel braided clutch lines. You can check on the functionality and performance of your vehicle’s clutch. This process removes trapped air within the hydraulic system, which can otherwise lead to a spongy clutch pedal and compromised engagement.

Without special tools, this is a two-person job, so get help from a friend! To bleed the clutch system, begin by locating the bleed screw on the clutch slave cylinder and ensuring the reservoir contains the recommended brake fluid. Using a clear hose attached to the bleed screw, have your partner press the clutch pedal while you slowly open the screw to release air and fluid. Close the screw before releasing the pedal, and repeat this process until only fluid flows through without air bubbles.

Take Control of Your Driving Experience Today

Replacing your factory clutch line with a steel braided model is one of the smartest moves you can make for your vehicle. From enhanced durability to improved pedal feel, the benefits are undeniable. Gain greater control and efficiency with a clutch modification that delivers long-term results.

Don’t settle for a spongy clutch or outdated factory components. Upgrade to the Clutch Masters stainless steel line today, and experience the difference firsthand. Your vehicle deserves nothing but the best!