Flywheel Dimension Issues to Watch for in Engine Swaps

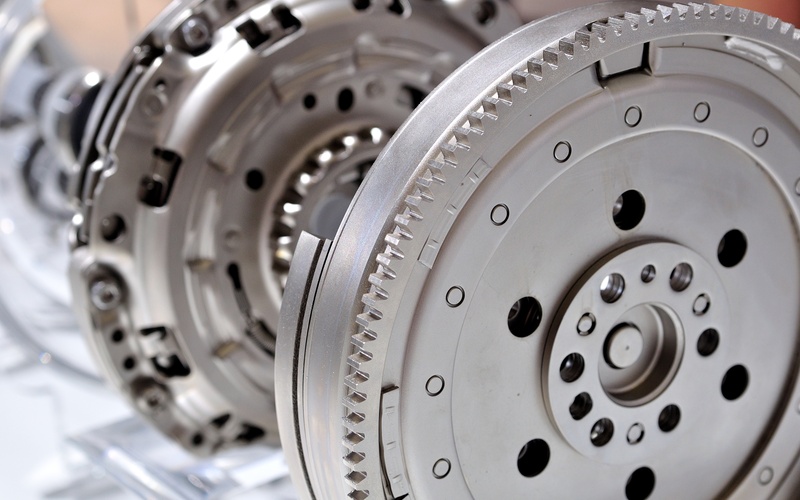

Engine swaps can transform ordinary vehicles into high-performance machines, but ensuring flywheel compatibility is crucial for reliable operation. The flywheel connects the engine's rotating assembly to the clutch system, and incompatible dimensions can cause vibrations, starter issues, or drivetrain failures.

With manufacturers using diverse specifications for bolt patterns, thickness, and balance, compatibility challenges are common, especially with modern engine swaps. In this guide, we’ll break down the common flywheel dimension issues to watch for in engine swaps to guarantee high performance and smooth functionality.

Understanding Key Flywheel Dimensions

Before we delve into the typical issues, it’s best to review the dimensions of flywheels to gain a firm grasp of how they work. Diameter, thickness, and tooth count are all key dimensions to consider in flywheels for engine compatibility.

Diameter and Bolt Pattern Specifications

Flywheel diameter is a crucial factor in ensuring compatibility with your clutch system. Racing applications often require larger flywheels to handle increased torque; however, the diameter must match the engine's crankshaft specifications and the clutch assembly. Standard automotive flywheels range from 9 inches for compact vehicles to over 14 inches for heavy-duty trucks, with high-performance variants typically between 10.5 and 12 inches.

Bolt pattern configuration dictates how the flywheel mounts to the crankshaft, with variations in bolt circle diameter and fastener count posing compatibility challenges. Common patterns include six-bolt setups for domestic V8 engines and eight-bolt designs for high-performance applications, while unique European patterns may require custom solutions.

Thickness and Offset Measurements

Flywheel thickness is also important in clutch component positioning and transmission input shaft alignment within the bellhousing. Incorrect thickness can cause spacing issues, which means clutch engagement problems or interference between rotating and stationary parts. High-performance setups often require specific thickness ranges to maintain clutch geometry and ensure proper clearance for pressure plate operation.

Offset measurements determine the flywheel's position relative to the crankshaft centerline, impacting balance and drivetrain clearance. Some setups need a neutral offset, while others use an intentional offset to align with engine mounting or transmission requirements.

Tooth Count and Balance Requirements

The tooth count on a ring gear is central to starter compatibility and engine cranking performance. Manufacturers often use different tooth counts, even within similar engine displacements, which can cause issues when swapping engines between platforms. Common setups include 153-tooth arrangements for many domestic vehicles and 168-tooth configurations for high-performance models, while European and Asian engines often follow entirely different specifications.

Flywheel balance is equally important for compatibility. Engine manufacturers carefully balance rotating assemblies to reduce vibration and maximize durability, with flywheel weight and balance playing key roles. Internal balance engines require neutral flywheels, while external balance setups rely on specific flywheel weight and positioning.

Common Dimension-Related Issues

Now that we understand more about flywheel dimensions, we can better watch out for common issues in engine swaps. Starter compatibility, clutch alignment, and excessive vibrations are all typical flywheel problems that can plague an engine swap.

Starter Compatibility Problems

Starter engagement issues typically stem from the flywheel dimension incompatibility. The positioning of the ring gear relative to the starter drive determines engagement depth and contact pattern. Incorrect dimensions can cause grinding noises, premature wear, or complete engagement failure. Tooth count mismatches further complicate compatibility by affecting gear reduction ratios and engagement timing, leading to grinding contact that quickly damages both the starter and ring gear.

Flywheel diameter and starter positioning also create clearance challenges that may only become evident during installation. Achieving proper engagement geometry can require starter relocation or modified mounting brackets, adding complexity and expense to what might seem like a simple swap.

Clutch Alignment Challenges

Clutch alignment issues can arise from variations in flywheel thickness and offset, disrupting the positioning of components within the bellhousing. This misalignment hinders proper engagement between the clutch disc and pressure plate, leading to slippage that rapidly wears down friction materials and diminishes performance. These issues tend to develop gradually, making early detection challenging until significant performance loss occurs.

Proper pressure plate compatibility depends on accurate flywheel surface preparation to ensure even clamping force distribution. Irregularities or dimensional mismatches can cause uneven loading, accelerating wear, and reducing holding capacity, especially critical in high-torque racing applications. Flywheel and clutch geometry also impact pedal feel and engagement, with dimensional mismatches leading to heavy pedal effort, inconsistent engagement points, or even disengagement.

Vibration and Balance Concerns

Improper flywheel dimensional matching can cause severe balance-related vibrations, which stress the entire drivetrain, from crankshaft bearings to transmission input shafts. These vibrations accelerate wear and can cause catastrophic failures, particularly in racing applications where high-RPM operation amplifies the effects. Harmonic resonance conditions can occur when the flywheel's balance interacts poorly with engine natural frequencies, creating destructive vibration patterns that may crack blocks, destroy bearings, or damage transmission cases.

Such vibration issues often manifest only at specific RPM ranges, making them difficult to diagnose until significant damage has already occurred. The effects of these vibrations ripple throughout the vehicle, impacting driveshaft alignment and chassis components. To prevent costly failures, professional racing teams monitor vibration levels closely, catching problems early before they lead to race-ending breakdowns or expensive repairs.

Best Practices for Avoiding Issues

Now that we know the common problems of flywheel dimensions and engine swaps, how do you prevent them? Careful research, measurement, and quality parts are all vital to ensuring an ideal fit of the flywheel and engine.

Research and Measurement Protocols

Dimensional analysis is key to assessing flywheel compatibility. Builders record measurements for donor and recipient engines, creating reference databases to streamline future projects and avoid repeated errors. These measurements cover everything from diameter and thickness to balance and offset requirements, ensuring precision at every step.

Cross-referencing parts helps identify compatible components across manufacturers and applications. Many aftermarket suppliers offer aftermarket flywheels that bridge compatibility gaps, but verifying specifications guarantees proper fit and performance. Documenting successful combinations creates valuable references, reducing risk and saving time, especially for racing teams looking to avoid costly mistakes.

Professional Consultation Benefits

Experienced engine builders bring valuable expertise to flywheel compatibility assessments, going beyond basic dimensional matching. Their deep understanding of dynamic balance requirements, material compatibility, and performance optimization confirms a smooth engine swap and prevents costly issues. This expertise is especially critical for complex projects or high-performance applications.

When standard components fall short, machine shops provide custom solutions. They can modify flywheel dimensions, perform custom balance corrections, or fabricate new components to meet unique needs.

Quality Parts

Component quality is a priority for compatibility and longevity in demanding racing applications. Premium manufacturers like Clutch Masters use precision manufacturing and high-quality materials to ensure dimensional accuracy and consistent performance over extended service intervals. Proper installation is equally important—following the manufacturer's specifications, including surface preparation, torque settings, and assembly techniques, is a requirement to avoid premature failure and ensure reliability.

Achieving Swap Success Through Dimensional Precision

Flywheel-dimensional compatibility prevents issues like vibration, wear, and reliability problems. The racing community shows that attention to dimensional details ensures optimal performance and avoids costly mistakes.

Investing in proper analysis and quality components improves reliability, performance, and reduces maintenance. Partnering with experts like Clutch Masters provides access to precision-engineered flywheels and expert support, turning your performance vision into a reliable, track-ready reality. Browse our available racing flywheels online, or contact our staff to speak with an expert today.