What is Flywheel Inertia & How Does It Affect Acceleration?

Flywheel inertia is a critical factor influencing your vehicle's acceleration. This rotational property dictates how quickly your engine can change RPM, directly affecting launch acceleration and throttle response. For any enthusiast aiming to optimize vehicle performance, grasping flywheel inertia is fundamental.

Professional racers and performance enthusiasts recognize the flywheel as a prime area for modification, as reducing rotational mass significantly enhances performance. This allows for quicker rev matching, faster acceleration between gears, and superior overall engine responsiveness. Keep reading to better understand what flywheel inertia is, how it affects acceleration, and more.

Understanding Flywheels

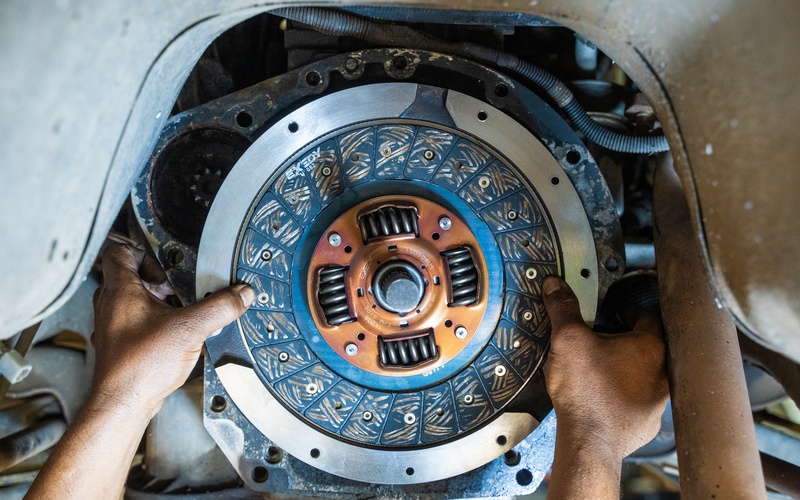

First, let’s review the flywheel and its critical role in vehicle performance. Flywheels are energy storage devices in an engine's rotating assembly that directly attach to the crankshaft. They store rotational energy during power strokes and release it during non-power strokes to provide consistent engine operation between combustion events. Beyond energy storage, flywheels provide a mounting surface for the clutch system and maintain inertial balance, smoothing out power pulses during idle and facilitating smooth operation during gear changes and load transitions, especially at low RPMs.

Along with maintaining momentum, flywheels act as heat sinks, absorbing and dissipating the thermal energy that engaging the clutch produces. This thermal management helps preserve consistent friction characteristics and extend clutch life. Many aftermarket flywheels feature special materials and designs to enhance heat dissipation and overall performance.

Explaining Inertia

Inertia is an object's resistance to any change in its state of motion. For a rotating component like a flywheel, the object’s total mass and its distribution relative to the axis of the rotation determine its rotational inertia. According to physical principles, mass farther from the central axis contributes exponentially more to the total inertia. This means a flywheel's outer diameter has a much greater impact on its inertial properties than its thickness or inner diameter.

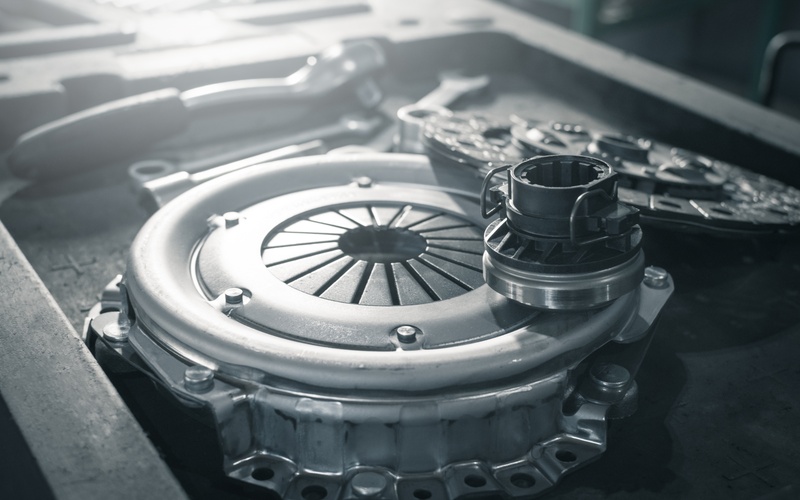

This principle allows engineers to fine-tune a flywheel's performance by strategically placing mass, such as with a ring-style design that concentrates mass at the outer edge versus a solid disk that distributes it more evenly. Environmental and operational factors also influence the performance implications of inertia. High RPMs generate significant centrifugal forces that create stress, while temperature fluctuations can alter material properties. Therefore, the choice of material is critical. High-grade materials, such as the 6061-T6 billet aluminum that Clutch Masters uses in their flywheels, maintain structural integrity and consistent inertial properties under the extreme stress and temperature variations of high-performance driving.

Flywheel Inertia & Acceleration

Now that we know more about flywheels and the principles of inertia, how does it affect acceleration? The lower the flywheel inertia, the greater the vehicle acceleration.

The Direct Relationship: Lower Inertia, Faster Acceleration

Lower flywheel inertia directly translates to greater acceleration. This is because it significantly reduces the rotational mass your engine must overcome.

When you engage the throttle, the engine's torque accelerates the flywheel. By reducing this inertial load, a greater proportion of engine torque is immediately available to propel the wheels, culminating in superior acceleration performance.

Enhanced Responsiveness and Precision Driving

The advantages of reduced flywheel inertia become particularly apparent during dynamic driving, particularly during rapid throttle transitions and gear changes. Lightweight flywheels allow engines to rev with remarkable speed, facilitating precise throttle blips for heel-toe downshifting or seamless rev-matching. This immediate, responsive engine behavior enhances driver control and enables more refined, aggressive driving techniques.

Contrasting Effects: The Role of Higher Inertia

Conversely, higher flywheel inertia introduces a different dynamic, demanding more time and energy to alter engine speed. While heavy flywheels store substantial rotational energy, making them slower to accelerate, they also resist deceleration. This inherent characteristic can, in specific driving contexts, offer advantages by sustaining momentum during momentary throttle lifts, influencing vehicle behavior in distinct ways.

RPM-Dependent Acceleration Benefits

Performance drivers should also understand that the inertia-acceleration relationship manifests differently across various engine RPM ranges. Low-RPM acceleration experiences the most significant gains from a lighter flywheel, largely because engines naturally produce less torque at these lower speeds. As engine RPMs climb and torque output increases, the benefit to high-RPM acceleration, while still present, becomes less dramatic, as the engine possesses greater intrinsic power to overcome the inherent inertial resistance.

Benefits of a Lightweight Flywheel

The lower inertia of a performance flywheel provides many benefits to drivers who want to maximize their vehicle’s performance. Greater acceleration, less turbo lag, and optimized torque are all advantages that a lightweight flywheel provides.

Enhanced Acceleration and Responsiveness

The most immediate and discernible advantage of a reduced flywheel weight is better acceleration. Engines with a lightweight flywheel exhibit greater responsiveness to throttle inputs, facilitating faster rev-matching and more rapid acceleration through the gears. This heightened responsiveness is not merely a track-day luxury; it fundamentally enhances both aggressive performance driving and the nuanced demands of daily operation, providing a more engaging and direct connection between driver and machine.

Mitigated Turbo Lag

For vehicles with forced induction, particularly turbocharged vehicles, a lightweight flywheel offers a critical advantage: substantially reduced turbo lag. By reducing rotational inertia, lighter flywheels enable engines to build RPM more quickly.

This acceleration in engine speed directly translates into quicker turbocharger spooling, drastically reducing the time necessary to reach optimal boost levels. The result is a sharper, more immediate throttle response and a palpable improvement in overall acceleration characteristics in turbocharged applications.

Efficiency for Supercharged Engines

Supercharged powertrains also benefit from the integration of a lightweight flywheel. The reduction in rotational mass directly diminishes crankshaft drag. This means the supercharger demands less power from the engine to maintain its operational RPM, effectively freeing up more usable power. This efficiency gain translates into a tangible increase in available horsepower and torque, directly contributing to superior performance.

Optimal Mid-Range Torque

Naturally aspirated engines experience notable improvements in mid-range torque when adopting a lightweight flywheel. The reduced inertial load allows the engine to accelerate more readily and efficiently through the critical mid-RPM range—the band where the majority of street driving occurs. This characteristic elevates everyday drivability, makes the vehicle feel more eager and responsive, and enhances performance across the powerband.

Maximizing Performance Through Proper Flywheel Selection

Optimizing your vehicle's performance hinges on selecting the correct flywheel, a choice that carefully balances your performance objectives with its intended use. While track-specific applications can prioritize extreme weight reduction for ultimate gains, daily drivers demand a thoughtful compromise to maintain superior drivability. Regardless of your focus, precision is paramount; professional installation ensures flawless operation and maximizes longevity.

Enhance Your Performance Car With Clutch Masters Industries

Understanding the profound impact of flywheel inertia empowers you to make informed decisions, resulting in tangible improvements in vehicle responsiveness and acceleration. This deep dive into rotational physics isn't just theoretical; it delivers real-world performance benefits that elevate your driving experience. For expert guidance on flywheel and clutch solutions for superior performance and unmatched durability, trust Clutch Masters Industries to power your drive.