Common Causes and Symptoms of a Failing Flywheel

Your vehicle's flywheel is integral for engine operation, connecting the engine to the transmission, storing rotational energy, and providing smooth power delivery. Many drivers only notice its importance when problems arise, which can range from minor performance issues to complete transmission failure. Recognizing the warning signs early can prevent costly repairs and dangerous driving situations, as a failing flywheel disrupts the delicate mechanical synchronization of modern vehicles.

Flywheel failure can stem from many things, like normal wear, aggressive driving, environmental factors, improper maintenance, or installation errors. In this guide to automotive flywheels, we’ll explain the common causes and symptoms of failing flywheels so drivers can prevent such issues and diagnose problems when they do arise.

Understanding Your Vehicle's Flywheel

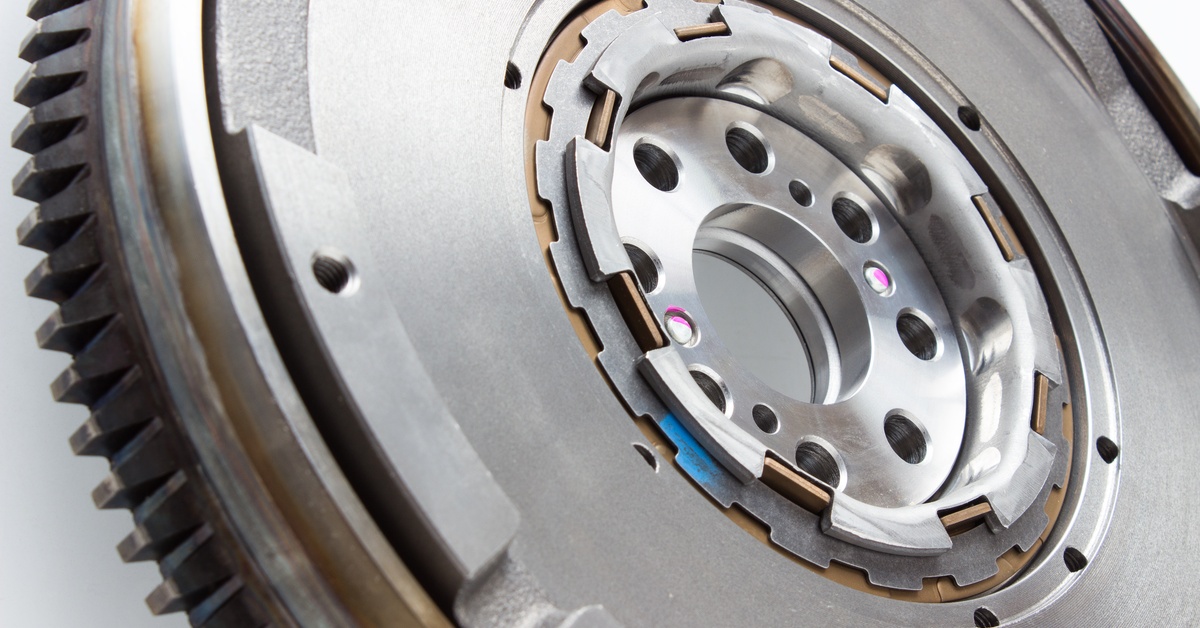

First, drivers must understand what their vehicle’s flywheel is and its role. The flywheel acts as a mechanical energy storage device, maintaining engine momentum between combustion cycles. This heavy metal disc on your engine's crankshaft stores rotational energy during power strokes and releases it during compression and exhaust. It also provides the crucial mounting surface for your clutch assembly in manual transmissions or the torque converter in automatics, making it essential for both engine smoothness and power transmission.

There are various types of materials for modern flywheels depending on their application. Stock flywheels typically use cast iron or steel for durability and heat dissipation. However, performance applications demand lightweight alternatives like aluminum or specialized steel alloys.

Primary Causes of Flywheel Failure

When a flywheel fails, it’s typically not a mystery. Common causes for flywheel failure include normal degradation, damage to the clutch, overheating, and even aggressive driving patterns.

Normal Wear and Degradation

Time and mileage inevitably take their toll on flywheel components. The constant heating and cooling cycles that occur during normal driving cause metal expansion and contraction, gradually weakening the flywheel's structure.

Surface wear develops on the friction area where the clutch makes contact, creating grooves and hot spots that reduce clutch effectiveness. High-mileage vehicles may experience flywheel cracking around bolt holes or stress concentration points due to repeated loading cycles over hundreds of thousands of miles.

Clutch Damage

A worn or improperly adjusted clutch creates excessive friction and heat that damages the flywheel surface. When clutch friction material deteriorates, metal-to-metal contact occurs between the clutch disc and flywheel, causing severe scoring and heat damage.

Riding the clutch pedal or incomplete clutch disengagement forces the clutch to slip continuously, generating destructive heat that warps the flywheel. Oil leaks from rear main seals or transmission input shaft seals contaminate the clutch assembly, causing erratic engagement that accelerates flywheel wear patterns.

Overheating Conditions

Excessive heat represents one of the most destructive forces affecting flywheel longevity. Aggressive driving habits like frequent hard launches, extended high-RPM operation, or repeated clutch slipping generate temperatures that exceed the flywheel's metallurgical limits.

This overheating causes warping, cracking, and changes in the metal's hardness properties. Racing applications without proper cooling considerations may experience thermal stress that creates radial cracks extending from the center mounting area toward the outer friction surface.

Installation Errors

Any automotive part can cause problems in a vehicle if the installation is sloppy or incorrect. Improper flywheel installation creates stress concentrations that lead to premature failure. Incorrect bolt torque specifications can cause uneven clamping forces that warp the flywheel or create stress risers around bolt holes.

Using damaged or worn bolts compromises the mounting integrity and allows the flywheel to shift during operation. Failure to properly align the flywheel during installation results in runout conditions that cause vibration and accelerated wear throughout the drivetrain.

Aggressive Driving Patterns

Drivers must also be wary of how they drive and how it can affect their car’s flywheel. High-performance driving places extraordinary demands on flywheel components. Frequent hard launches create sudden shock loads that can crack lightweight flywheels not designed for such abuse.

Aggressive shifting techniques that involve rapid clutch engagement generate heat spikes and impact loads beyond normal operating parameters. Track driving without appropriate cooling modifications will subject flywheels to high temperatures that cause metallurgical changes and fatigue.

Recognizing Flywheel Failure Symptoms

Now that we know the common causes of a failing flywheel, what about symptoms? If you notice these signs of problems while driving, the issue is likely your vehicle’s flywheel.

Vibration Through the Drivetrain

A warped or cracked flywheel creates noticeable vibrations that transmit through the entire vehicle. These vibrations intensify under acceleration and may feel like a rhythmic pulsing through the clutch pedal, steering wheel, or seat.

The vibration frequency typically correlates with engine RPM, becoming more noticeable as engine speed increases. Severe flywheel damage can create vibrations violent enough to loosen other components or cause premature wear in transmission mounts and driveline components.

Clutch Slippage Issues

Flywheel surface damage directly affects clutch engagement characteristics. Grooved or warped flywheel surfaces prevent uniform contact between the clutch disc and flywheel, reducing the clutch's ability to transfer engine torque effectively.

This slippage becomes most apparent during acceleration, especially when climbing hills or carrying heavy loads. You might notice engine RPM increasing without corresponding vehicle acceleration, or the clutch engagement point changing during operation.

Shifting Difficulties

A damaged flywheel disrupts the operation of your transmission's synchronizers and shift mechanisms. The resulting vibrations and inconsistent clutch engagement make it difficult to achieve clean shifts, particularly into first gear from a stop or when downshifting.

You may experience grinding noises during shifting, or require more effort to shift the lever, or feel the transmission jumping out of gear unexpectedly. These symptoms will worsen as the flywheel damage progresses.

Unusual Operating Noises

Flywheel problems generate distinctive sounds that experienced mechanics can identify immediately. Grinding noises during clutch engagement indicate metal-to-metal contact between damaged surfaces.

Glazed flywheel surfaces or contamination of the clutch components can cause squealing sounds in the clutch. Rattling noises at idle may indicate loose flywheel bolts or cracked flywheel sections. These audio cues typically accompany other symptoms and provide valuable diagnostic information about the extent of flywheel damage.

Performance Degradation

A failing flywheel negatively impacts overall vehicle performance in multiple ways. Reduced acceleration capability occurs when clutch slippage prevents efficient power transfer from the engine to the transmission.

Engine performance feels less responsive due to irregular flywheel mass distribution affecting rotational smoothness. These performance issues typically develop gradually, making them difficult to notice until the damage becomes severe.

Advantages of Lightweight Performance Flywheels

If you need to replace a failing flywheel, a lightweight flywheel is worth your consideration. Upgrading to a lightweight performance flywheel enhances vehicle dynamics by reducing rotational mass, leading to faster acceleration as the engine directs more energy toward propulsion. This is particularly advantageous in racing, where even small-time gains are crucial.

Performance flywheels also bring practical benefits. Aluminum flywheels feature replaceable friction surfaces, cutting down on long-term maintenance costs by eliminating the need for resurfacing. Their precision manufacturing also improves balance and reduces vibration compared to worn stock units, making them an ideal choice for high-performance applications.

Upgrade Your Vehicle's Flywheel with Clutch Masters

When flywheel replacement becomes necessary, choosing high-quality performance components ensures reliable operation and enhanced vehicle capabilities. Clutch Masters’ performance flywheels undergo rigorous design and testing procedures to guarantee safety and quality standards that surpass expectations. Browse our inventory to find the ideal flywheel for your vehicle, or contact our staff to speak with an expert today.