Flywheel Friction Lock

Flywheel Friction Lock, Surface Lock,

Description

Sometimes it takes a leap in technological advancement to solve those problems. One issue a lot of high powered cars can run into is the possibility of the flywheel coming loose. Flywheels can come loose for a variety of reasons, but once this happens you can pretty much kiss your crank goodbye. Typically if the flywheel comes loose it will end up welding (fretting) itself to the crankshaft and typically damages the crank beyond repair. This can end up being an incredibly costly problem.

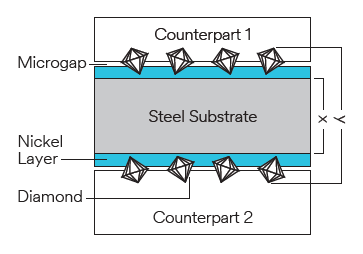

We've teamed up with global engineering powerhouse, 3M, to offer their friction shim technology specially developed for flywheel applications to provide that extra level of protection. Dubbed Flywheel Friction Locks, our FFLs consist of a nickel-coated steel substrate with partially embedded diamond particles. When placed between the flywheel and crank, the diamonds “bite” into each surface. With an installed thickness of .006"-.009" an FFL will not significantly alter assembly spacing. FFLs are easy to assemble and can be reused after disassembly.

Flywheel Friction Shim Cross Section:

To sum that up, by installing a Flywheel Friction Lock you give yourself a much better chance of the flywheel not coming loose in the first place, and if for some reason it does, you'll have an extra layer of very hard steel that can prevent the flywheel from damaging your crankshaft. It has been proven that our FFLs offer a simple and cost-effective way to reliably handle up to 5× higher shear forces and transmit up to 5× higher torque than conventional systems with no other modifications.

Details

- CM-037-FFL

- CM-037-FFL

- Clutch Masters

- New

Categories

Shipping Information

- Item Requires Shipping

- 1.0 lbs.

- This item ships in its own box.

Customer Reviews

Total Reviews (0)

Total Reviews (0)

You must login to post a review.

Write the First Review!